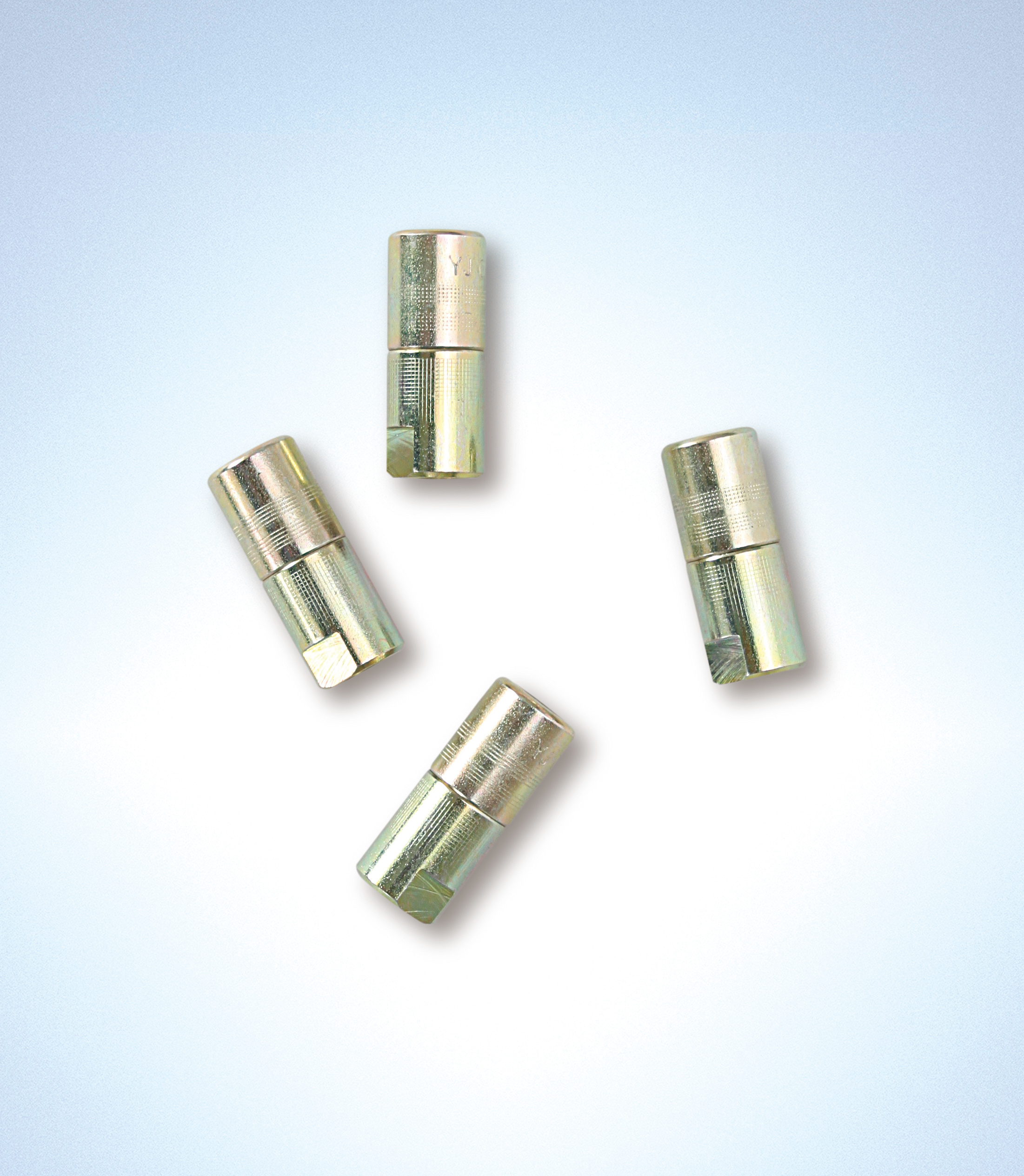

MECHANICAL INJECTION GROUTING PACKER

Price 45 INR/ Piece

MECHANICAL INJECTION GROUTING PACKER Specification

- Packaging Size

- Available in bulk; minimum order quantity is 10 units

- Usage & Applications

- Sealing cracks and joints in concrete, tunnels, dams, sewers, and other underground structures

- Type

- Mechanical Injection Packer

- Material

- Aluminum, Brass, Zinc

- Color

- White

MECHANICAL INJECTION GROUTING PACKER Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Busan / Incheon

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Certifications

- Manual

About MECHANICAL INJECTION GROUTING PACKER

Injection Grouting Packer

It is a expendable tools for using to inject Polyurethane and Epoxy into concrete cracks. Packers bear up against high pressure,have strong durability,and were designed for easy installation and easy removal. Also, we manufacture all sizes which are able to cover whole construction industry.

| 8 X 55mm | ||

| 10 X 60mm | 10 X 100mm | 10 X 140mm |

| 13 X 70mm | 13 X 120mm | 13 X 150mm |

| 14 X 70mm | 14 X 120mm | 14 X 150mm |

Reliable Solution for Concrete Repairs

Mechanical Injection Grouting Packers offer a robust and efficient method for sealing cracks and joints in key infrastructure projects. By providing a secure channel for PU foam, epoxy, or acrylic resin injection, these packers ensure the long-term integrity of tunnels, sewers, and other concrete structures. Their versatility in size and composition makes them compatible with a wide range of repair tasks.

Versatile Material and Size Range

Constructed from high-quality aluminum, brass, and zinc, the mechanical packers cater to varying application needs. Their availability in multiple dimensions and weights ensures adaptability for any repair scenario, making them suitable for both large-scale and specialized projects.

FAQs of MECHANICAL INJECTION GROUTING PACKER:

Q: How is a mechanical injection grouting packer used in concrete structure repairs?

A: The packer is installed into pre-drilled holes along cracks or joints. Grouting material such as PU foam, epoxy resin, or acrylic resin is then injected through the packer under pressure, filling and sealing voids to restore the structural integrity of concrete.Q: What materials can be injected using this mechanical packer?

A: These packers are compatible with polyurethane (PU) foam, epoxy resin, and acrylic resins, making them ideal for a variety of concrete crack and joint repair applications.Q: When should I use a mechanical injection packer instead of a chemical or adhesive solution?

A: You should use a mechanical injection packer when high-pressure grouting is required for deeper or wider cracks, especially in critical infrastructure like tunnels, dams, sewers, or any scenario where robust sealing is necessary.Q: Where can mechanical injection packers be applied?

A: They are mainly used in underground and concrete structures, including tunnels, dams, sewers, basements, and parking garages, wherever durable crack and joint sealing is needed.Q: What is the installation process for these mechanical packers?

A: The process involves drilling a hole at the desired location, inserting the packer, tightening it to establish a secure seal, and then injecting the chosen grout material using an injection pump.Q: What are the main benefits of using mechanical injection packers?

A: They allow for controlled, high-pressure injection of repair materials directly into problem areas, ensuring thorough sealing. The packers robust construction and various sizes enhance adaptability and long-term performance in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in INJECTION PACKER GROUTING Category

PU INJECTION GROUTING

Minimum Order Quantity : 10 Gallons

Type : Other

Color : Transparent Light Ivory

Material : Single Component Semirigid Polyurethane Resin

PU injection Grout 2 component

Price 850 INR / Kilograms

Minimum Order Quantity : Depend upon Requirement Gallon

Type : Other

Color : Resin Dark Brown , Hardener Colorless Transparent

Material : Polyurethane Foam Resin

Packaging Size : 20 kg per pail

Quick Setting Cement / Mortar

Minimum Order Quantity : Depend upon requirement Kit

Type : Other

Color : Grey

Material : Quick setting water stop Mortar/Cement

injection grouting PU

Minimum Order Quantity : 10 Pieces

Type : Other

Color : Ivory

Material : Polyurethane Foam (Resin)

|

CONREPAIR CO.,LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry