PU / EPOXY Injection Grouting

Price 1000 USD ($)/ Piece

PU / EPOXY Injection Grouting Specification

- Packaging Size

- 20 kg per pail

- Usage & Applications

- Sealing cracks and joints in concrete, tunnels, dams, sewers, and other

- Water Absorption

- Hydrophobic

- Chemical Form

- Liquid

- Type

- Waterproof Membrane

PU / EPOXY Injection Grouting Trade Information

- Minimum Order Quantity

- 100 Packs

- Supply Ability

- 1000 Packs Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About PU / EPOXY Injection Grouting

Pu Foam (Grout)

Defective concrete.(Cracked or Honeycombed)- Concrete joints, Limestone, Brick construction. Pipe intrusions, Waste water tanks. Tunnels, Dams, Subway(Metro), Sewers, Utility boxes, etc.

- Defective concrete (cracked or honeycombed)

- Concrete joints, Limestone, Brick construction

- Pipe intrusions, Waste water tanks

- Tunnels, Dams, Subway(Metro), Sewers, Manholes, Utility boxes, etc.

- Soil stabilization

- Negative side application possible

- Deep penetration into very small cracks

- Foam increases in volume to fill cavities and voids

- Excellent bond to surfaces

- Good adhesive strength, tolerant of movement

- Inert after curing, constant volume, no shrinkage

- Dose not create new cracks

| Form | Liquid Type |

|---|---|

| Color | Dark Brown |

| Solubility in Water | Hydrophobic |

| Density (g/ml) | 1.12 |

| Viscosity (KS F 4923) | 81 mPas |

| Max. Expansion (25) | 2,252 % [Ratio 10:1 Resin : Water] |

| Induction Time (25) | 15 sec [Ratio 2:1 Resin : Water] |

| Gel Time (25) | 110 sec [Ratio 2:1 Resin : Water] |

| Tensile shear strength (23), (KS M 3705) | 4 N/mm2 |

| Appearance | Light yellow Polyurethane Foam |

| Corrosiveness | Non-Corrosive |

| Chemical Resistance | Resistant to more organic Solvent, Mild Acids, Alkali |

| Shelf Life | 1 year when unopened and undamaged |

| Storage Condition | Store in a dry cool place |

| Packaging | 20 kg/pail |

Advanced Waterproofing Solution

PU/Epoxy Injection Grouting delivers a powerful waterproof membrane for both structural repairs and preventive maintenance. Its hydrophobic nature ensures minimal water absorption, making it ideal for use in demanding environments requiring robust moisture protection.

Versatile Applications

Ideal for sealing cracks and joints in concrete, this injection grouting is widely used in infrastructure like tunnels, sewers, and dams. Its liquid form enables deep penetration and effective sealing, protecting your structures from potential water damage.

FAQs of PU / EPOXY Injection Grouting:

Q: How is PU/Epoxy Injection Grouting applied to concrete structures?

A: PU/Epoxy Injection Grouting is injected into cracks or joints using specialized equipment. The liquid chemical fills voids and gaps, then cures to form a waterproof membrane, effectively sealing the targeted area.Q: What types of projects benefit most from using PU/Epoxy Injection Grouting?

A: This grouting is well-suited for tunnels, dams, sewers, and other concrete structures that require reliable sealing of cracks and joints to prevent water penetration and structural deterioration.Q: When should PU/Epoxy Injection Grouting be used during construction or repairs?

A: It should be applied whenever cracks or joints are detected, especially before signs of water leakage or after any structural movement that might compromise water tightness.Q: Where can PU/Epoxy Injection Grouting be sourced?

A: The product is available globally through distributors, exporters, manufacturers, suppliers, and traders, with South Korea being a notable origin for quality variants.Q: What is the process for injecting this chemical grouting?

A: The process involves cleaning the crack or joint, setting port injectors, and injecting the PU/Epoxy solution under controlled pressure to ensure deep penetration and effective sealing.Q: What are the key benefits of using hydrophobic PU/Epoxy grouting?

A: Its hydrophobic property offers superior resistance to water ingress, enhances structural durability, and minimizes maintenance needs by preventing water-related damage over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in INJECTION PACKER GROUTING Category

PU INJECTION GROUTING

Minimum Order Quantity : 10 Gallons

Type : Other

Material : Single Component Semirigid Polyurethane Resin

Color : Transparent Light Ivory

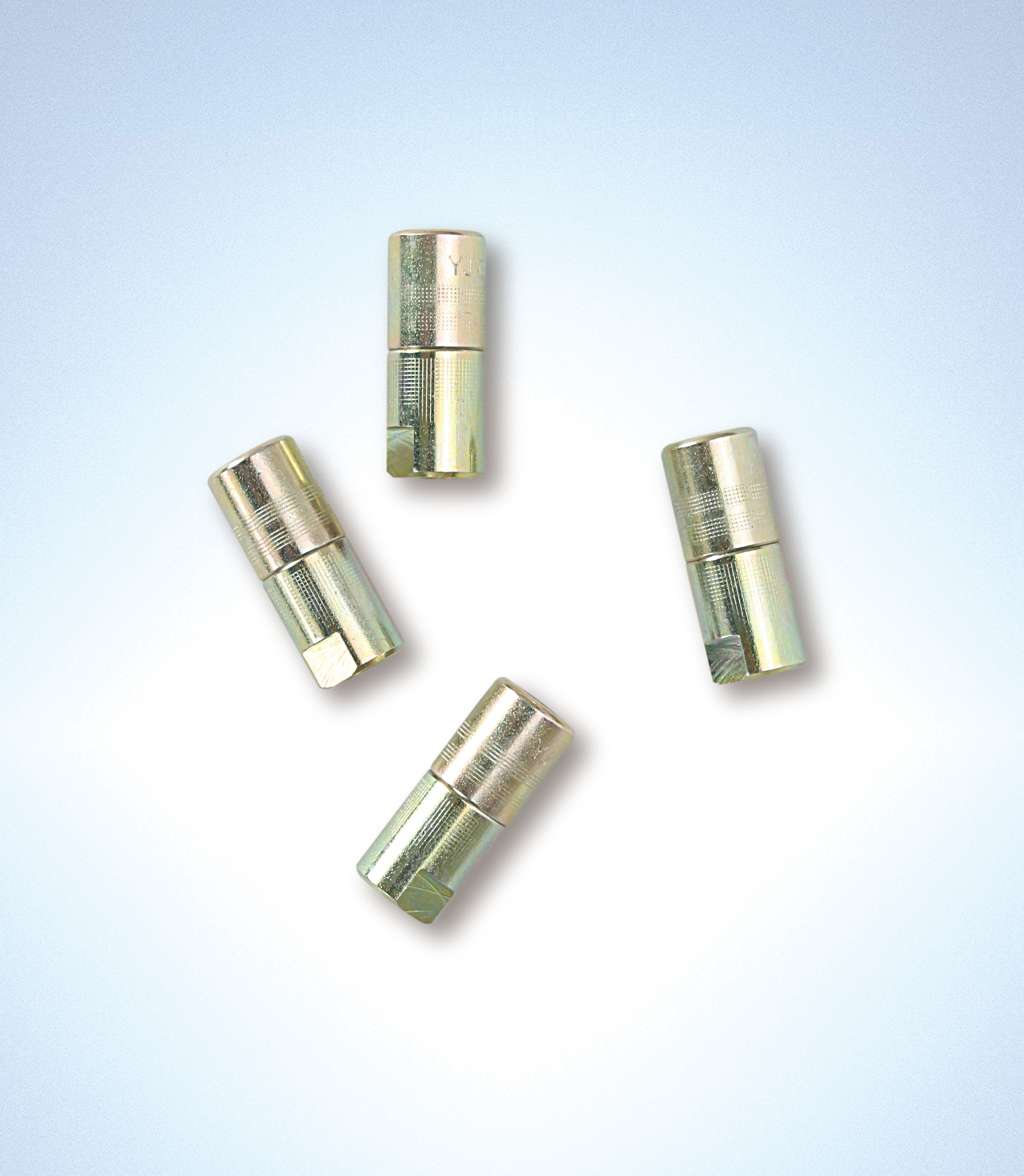

MECHANICAL INJECTION GROUTING PACKER

Price 45 INR / Piece

Minimum Order Quantity : 10 Pieces

Type : Other, Mechanical Injection Packer

Material : Other

Color : Other

Usage & Applications : Sealing cracks and joints in concrete, tunnels, dams, sewers, and other underground structures

PU injection Grout 2 component

Price 850 INR / Kilograms

Minimum Order Quantity : Depend upon Requirement Gallon

Type : Other

Material : Polyurethane Foam Resin

Color : Resin Dark Brown , Hardener Colorless Transparent

Usage & Applications : Sealing cracks and joints in concrete, tunnels, dams, sewers, and other

Quick Setting Cement / Mortar

Minimum Order Quantity : Depend upon requirement Kit

Type : Other

Material : Quick setting water stop Mortar/Cement

Color : Grey

|

CONREPAIR CO.,LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry