Showroom

Easy, swift and affordable to install, these Waterproofing Polyurethane systems are sure to enhance the life, quality and finishing of the floors. They are provided to enhance UV and weather resistant features.

These novel Syringe Injectors are the combination of heavy duty design and lightweight. With simple to operate design and durable structure, they are sure to provide the best results.

Grouting Machines are designed to conduct grouting professionally. They are compact, powerful and durable machines operated by electronic drills to develop pressure up to 5000 P.

Epoxy Adhesives are copolymers developed by mixing a resin and a hardener together. They are ideal to create durable and solid bonds in the manufacturing of paints, coatings, adhesives, plastics, primers, etc.

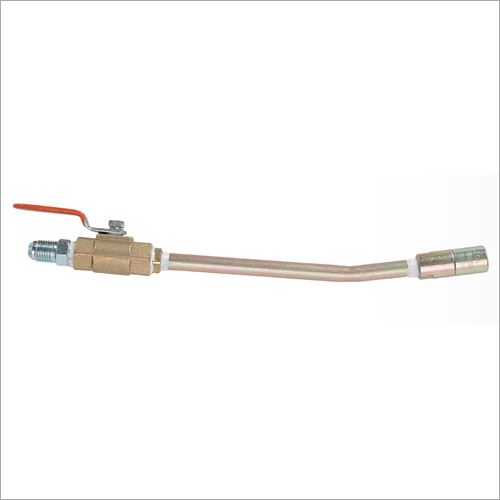

Sturdy and durable Injection Pumps are available in modern design to ensure maximum efficacy and performance. They are available in different sizes and dimensions to serve varied demands.

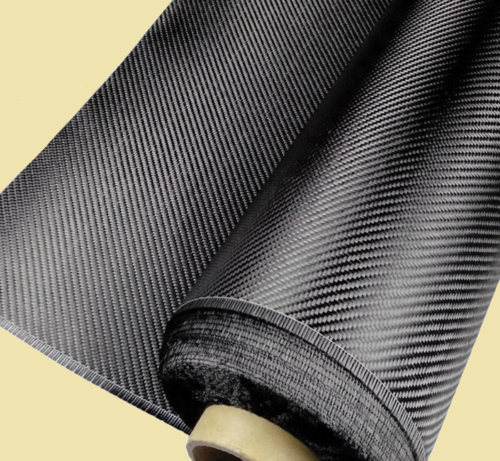

Carbon Fibers are available in different sizes from 5 to 10 micrometres in diameter. They are developed using carbon atoms to be used in textile, microelectrodes and other sectors.

Durable, reliable and strong Injection Pump Accessories are provided in different dimensions and specifications. They are sure to enhance the quality standards and performance level of pumps.

Epoxy Resin is widely used as structural and engineering adhesives owing to its strong-binding properties. It is widely used in the domain of construction of aircrafts, bicycles, vehicles, snowboards, etc.

Anti-abrasive, weather-resistant and rusting-proof Drain Plates are available in varied sizes to fit every need. They are available in durable design with anti-abrasive coating to ensure long lasting life.

|

CONREPAIR CO.,LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |